Products

CAST ROLLS

Cast rolls are manufactured by using either static or centrifugal casting techniques depending on the application, economy and availability.

Rolls can be supplied as finished plain or with rough turned/finished grooves as well as with the labyrinth (fillet) rings fitted on the necks.

One of the various grades fits every application in hot rolling of steel.

ROLL GRADES

- Cast Steel

- Adamite Steel Base

- Graphitic Steel

- Nodular Cast Iron (Ferritic-Pearlitic-Acicular)

- Indefinite Chill

- Clear Chill

- High Chromium Iron & Steel

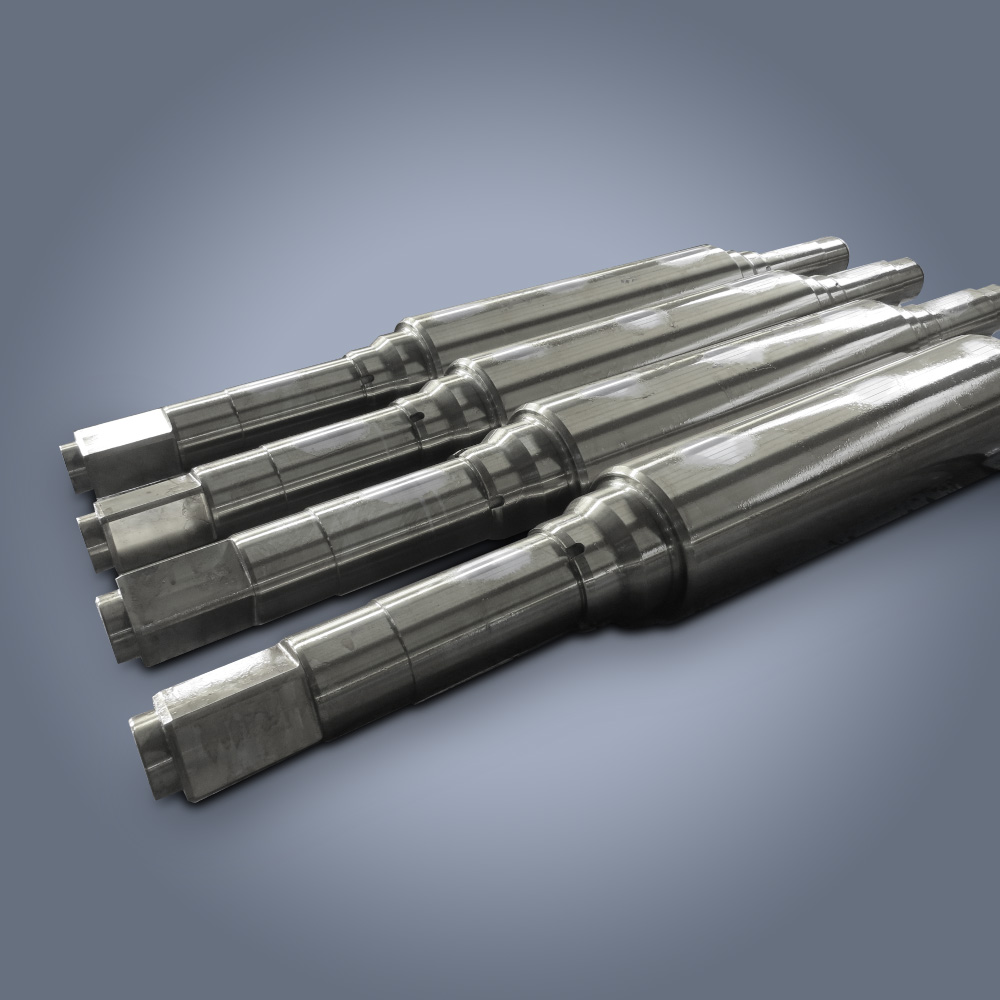

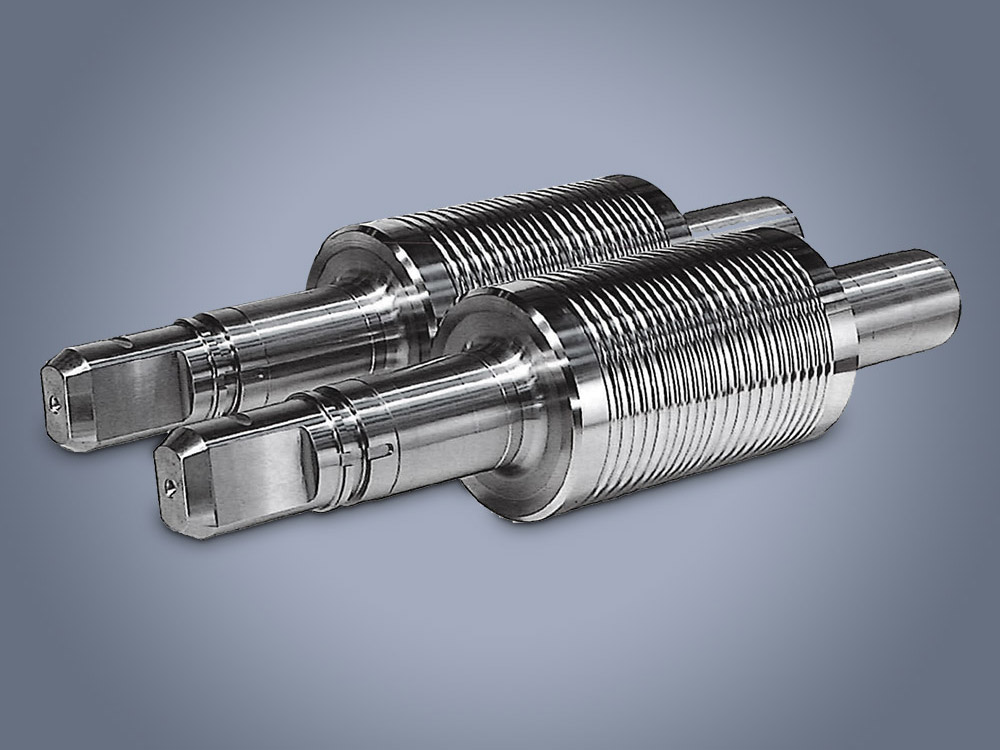

FORGED ROLLS & SHAFTS

High strength forged work rolls can be used in breakdown and roughing stands of bar and section mills. Forged roll shafts are available for universal stand rolls, composite rolls and straightening rolls.

Rolls and arbors can be made from various steel grades including Cr content of 2-5%, 42CrMo4, 65CrMn, 30CrNiMo8, 56NiCrMoV7 and more

- HSM Roughing and Finishing Backup Rolls

- HSM Roughing Stand Edger Rolls

- Heavy Section Mill BD rolls (flat or grooved)

- Universal Stand (UF/UR) roll shafts

Over the course of our business history, Marmacor has continued to expand its product range to remain a progressive supplier of all kind of mill rolls. High precision tools and engineering expertise ensure the highest quality and technical characteristics of the rolls we deliver.

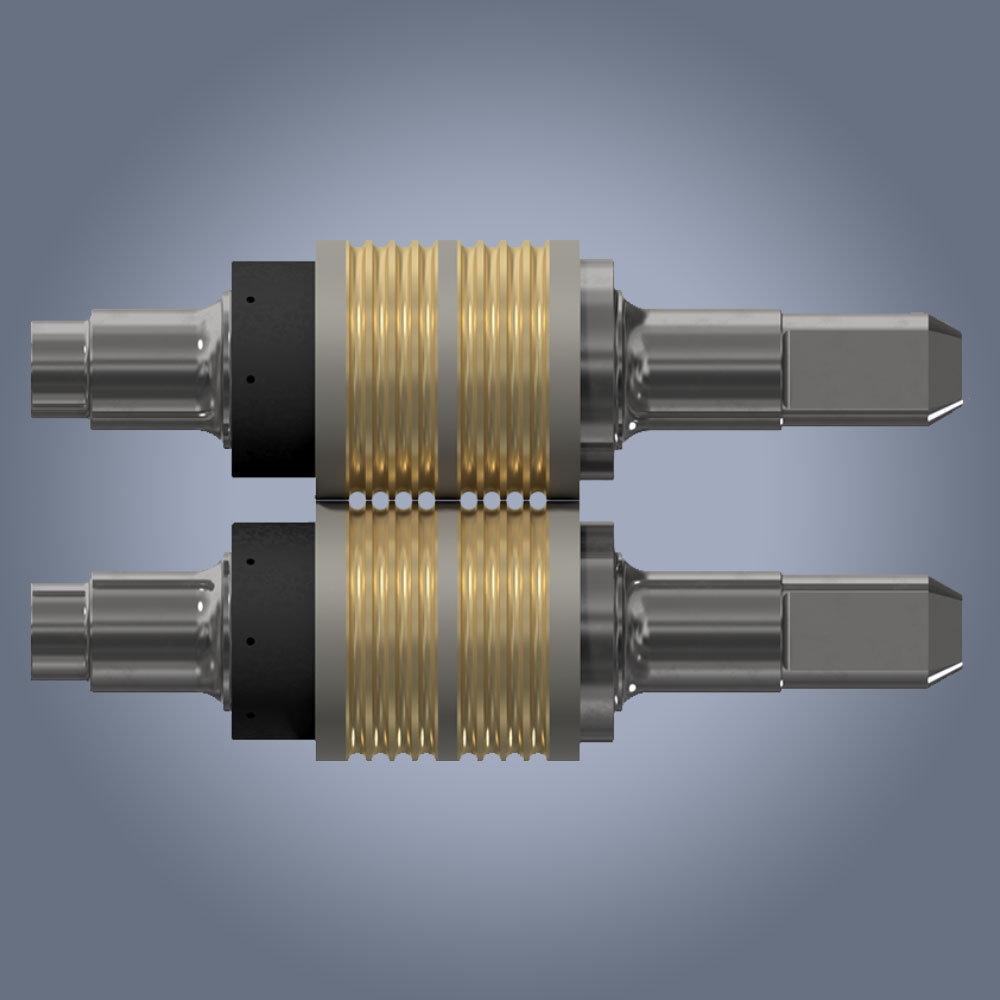

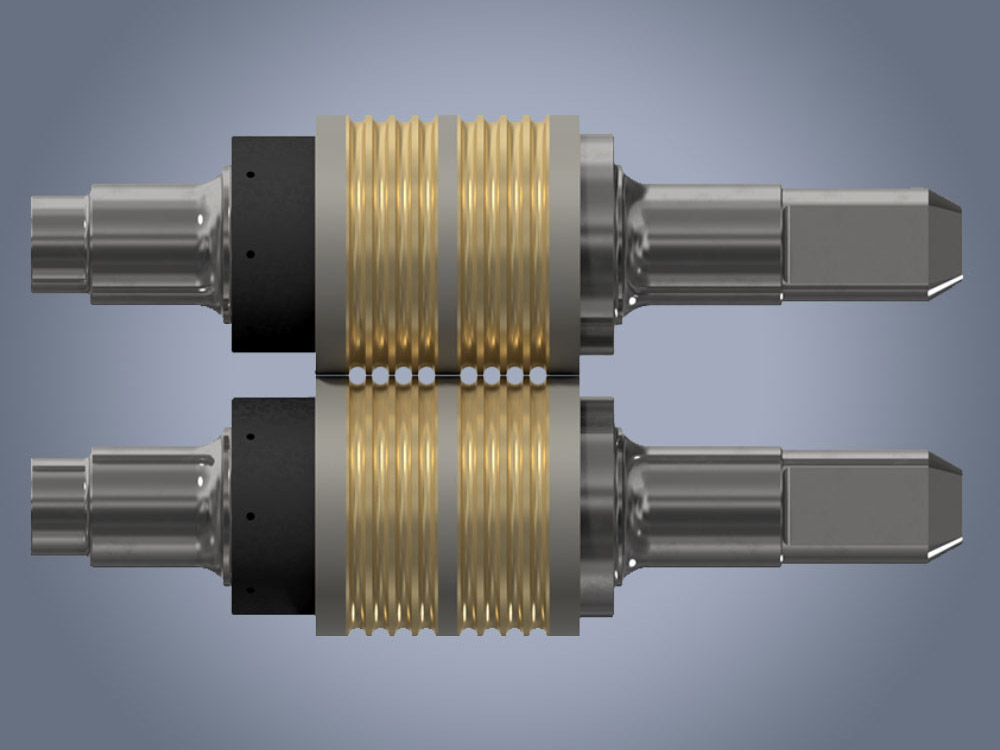

COMPOSITE ROLLS

Composite rolls are manufactured by mounting high performance rolling rings onto a forged steel shaft and fixing them by our patented hydraulic locking system. Like no other, our patented locking system does not include complicated parts, easy to assemble and disassemble the rings on the roll shaft.

Design parameters are decided in cooperation with the end user mill staff considering requirement of each specific mill.

In today’s modern mills, composite rolls are getting more popular which can give as much as 10 times higher pass life compared to conventional cast iron rolls.

HSS & TOOL STEEL ROLLS

High alloy HSS/Tool steel rolls are manufactured by centrifugal casting, continuous pouring casting method or by powder metallurgy techniques. Hence, a hard and wear resistant shell is metallurgically bonded onto the arbor resulting with a hard and wear resistant working layer on a tough and shock absorbent core in the same roll.

The minimum dia and the groove depth of each roll are the dictating parameters in deciding working layer thickness. Difference in alloying element content makes these rolls ideal for many applications including rebar finishers, dog-bone and slitters and from finishing to intermediate stands for all light and medium bar mills.

Other applications are;

- HSS & Semi HSS WR Rolls for HSM

- Tool Steel RSB Rolls

- Tool Steel Pinch rolls

- Tool Steel seamless tube rolls

- Tool Steel straightening rolls

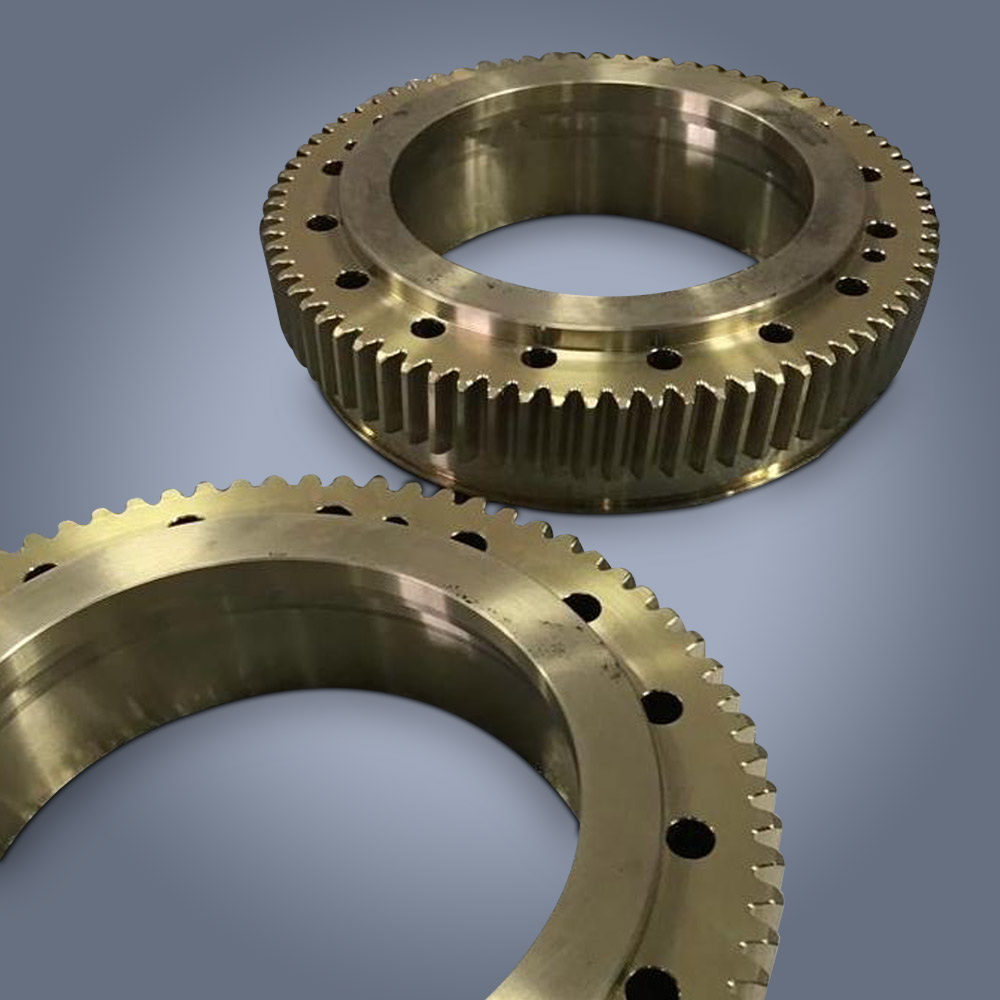

TUNGSTEN CARBIDE RINGS

Tungsten Carbide (TC) rings are the key elements in today’s high capacity and high speed wire rod mill and sizing blocks in order to achieve the best results with a smooth product surface and high capacity utilization of the mill. TC rings are also getting more popular in the bar mills for rolling rebars and light sections. TC rings are manufactured by powder metallurgy.

- TC WRM/RSB Finishing Block Rings

- TC Pinch Rolls

- TC Composite Roll Rings

MILL SPARES & CONSUMABLES

As important as the rolling mills are, without use of the proper consumables and support equipment, the rolling project would not be successful.

Marmacor provides various types of equipment and consumables needed to get the job done right. In addition, we are able to provide following services, consumables and accessories to help our clients produce accurate and the most effective rolling results from their mills.

Those items can be ordered in combination with your roll order as well as a separate order.

- PCD, CBN, inserts and notching tools

- Roll marking tools

- Diamond grinding wheels

- Rollers (Made of tool steel, Titanium or Tungsten carbide)

- Straightening rolls and rollers

- Labyrinth and spacer rings

- Neck rings

CAST ROLLS

Cast rolls are manufactured by using either static or centrifugal casting techniques depending on the application, economy and availability.

Rolls can be supplied as finished plain or with rough turned/finished grooves as well as with the labyrinth (fillet) rings fitted on the necks.

One of the various grades fits every application in hot rolling of steel.

ROLL GRADES

- Cast Steel

- Adamite Steel Base

- Graphitic Steel

- Nodular Cast Iron (Ferritic-Pearlitic-Acicular)

- Indefinite Chill

- Clear Chill

- High Chromium Iron & Steel

FORGED ROLLS & SHAFTS

High strength forged work rolls can be used in breakdown and roughing stands of bar and section mills. Forged roll shafts are available for universal stand rolls, composite rolls and straightening rolls.

Rolls and arbors can be made from various steel grades including Cr content of 2-5%, 42CrMo4, 65CrMn, 30CrNiMo8, 56NiCrMoV7 and more

- HSM Roughing and Finishing Backup Rolls

- HSM Roughing Stand Edger Rolls

- Heavy Section Mill BD rolls (flat or grooved)

- Universal Stand (UF/UR) roll shafts

Over the course of our business history, Marmacor has continued to expand its product range to remain a progressive supplier of all kind of mill rolls. High precision tools and engineering expertise ensure the highest quality and technical characteristics of the rolls we deliver.

COMPOSITE ROLLS

Composite rolls are manufactured by mounting high performance rolling rings onto a forged steel shaft and fixing them by our patented hydraulic locking system. Like no other, our patented locking system does not include complicated parts, easy to assemble and disassemble the rings on the roll shaft.

Design parameters are decided in cooperation with the end user mill staff considering requirement of each specific mill.

In today’s modern mills, composite rolls are getting more popular which can give as much as 10 times higher pass life compared to conventional cast iron rolls.

HSS & TOOL STEEL ROLLS

High alloy HSS/Tool steel rolls are manufactured by centrifugal casting, continuous pouring casting method or by powder metallurgy techniques. Hence, a hard and wear resistant shell is metallurgically bonded onto the arbor resulting with a hard and wear resistant working layer on a tough and shock absorbent core in the same roll.

The minimum dia and the groove depth of each roll are the dictating parameters in deciding working layer thickness. Difference in alloying element content makes these rolls ideal for many applications including rebar finishers, dog-bone and slitters and from finishing to intermediate stands for all light and medium bar mills.

Other applications are;

- HSS & Semi HSS WR Rolls for HSM

- Tool Steel RSB Rolls

- Tool Steel Pinch rolls

- Tool Steel seamless tube rolls

- Tool Steel straightening rolls

TUNGSTEN CARBIDE RINGS

Tungsten Carbide (TC) rings are the key elements in today’s high capacity and high speed wire rod mill and sizing blocks in order to achieve the best results with a smooth product surface and high capacity utilization of the mill. TC rings are also getting more popular in the bar mills for rolling rebars and light sections. TC rings are manufactured by powder metallurgy.

- TC WRM/RSB Finishing Block Rings

- TC Pinch Rolls

- TC Composite Roll Rings

MILL SPARES & CONSUMABLES

As important as the rolling mills are, without use of the proper consumables and support equipment, the rolling project would not be successful.

Marmacor provides various types of equipment and consumables needed to get the job done right. In addition, we are able to provide following services, consumables and accessories to help our clients produce accurate and the most effective rolling results from their mills.

Those items can be ordered in combination with your roll order as well as a separate order.

- PCD, CBN, inserts and notching tools

- Roll marking tools

- Diamond grinding wheels

- Rollers (Made of tool steel, Titanium or Tungsten carbide)

- Straightening rolls and rollers

- Labyrinth and spacer rings

- Neck rings

About

Since established in 1997,

Marmacor have been increasing

its presence in the global industry

as a reliable and long term

business partner.

Menu

Contact

Marmacor Dış Ticaret A.Ş.

Sahrayıcedit Atatürk Cad.

Mesa Koz Plaza, No: 69/222, Kadıköy

34734 İstanbul - Turkey

Phone: +90 216 373 1744

Fax: +90 216 373 1773

Copyright © 2021 Marmacor